Guangzhou Goodsense Decorative Building Material Co., Ltd

Views: 3 Author: Goodsense Publish Time: 2025-03-27 Origin: Site

In architectural decoration, industrial manufacturing, and even in the design and production of daily necessities, acrylic sheets and glass sheets are both commonly applied materials. Although both of them possess a certain degree of transparency, which can meet people's needs for daylighting and visual transparency, there are differences between the two in terms of appearance, physical properties, and processing techniques. Goodsense will guide you to understand these distinctions, which will be helpful for making appropriate material selections in different scenarios.

Differences in Appearance:

Acrylic sheets have good gloss and a soft texture. The surface is smooth, and it feels soft to the touch, giving people a texture similar to that of plastic. However, it is different from ordinary plastic and has the reputation of "plastic crystal". In addition to colorless and transparent acrylic sheets, they can also be made into sheets of various colors through the addition of pigments or dyeing processes, and the colors are vivid.

Glass sheets have a high gloss level, with a cold and hard texture. When touched, they feel icy cold. They are usually transparent and colorless, with relatively fewer color options. Moreover, the vividness and uniformity of the colors may not be as good as those of acrylic sheets.

Physical Differences:

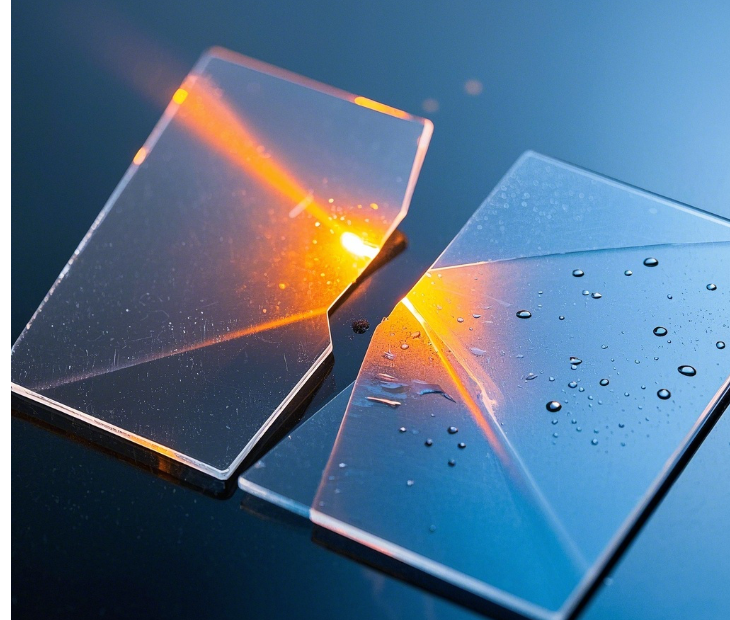

Glass exhibits poor toughness and weak impact resistance. When subjected to impact, it is highly likely to shatter and form sharp fragments. In contrast, acrylic sheets possess excellent toughness and remarkable impact resistance, which is approximately sixteen times that of ordinary glass. When they break, it is less likely for sharp fragments to be formed. As a result, in environments with specific high safety requirements, acrylic sheets are more frequently used.

For objects of the same volume, the density of acrylic sheets is lower than that of glass, and they are much lighter in weight, being roughly half the weight of glass. This characteristic makes them more convenient for handling and installation.

The light transmittance of acrylic sheets can reach over 92%, and the ultraviolet (UV) transmittance is 73%. In comparison, the light transmittance of ordinary glass is around 75%, and the UV transmittance is merely 0.6%.

Acrylic sheets demonstrate strong adaptability to the natural environment and can maintain color stability for an extended period when placed outdoors. Although glass has a certain level of weather resistance, after prolonged exposure to wind and sunlight, it may experience issues such as aging, weathering, and the growth of mold.

Acrylic sheets have excellent processability. They can be processed through methods such as thermoforming and mechanical processing. Additionally, they can be cut and engraved using a laser, making it easy to shape them into various complex forms. In contrast, the processing of glass sheets is relatively more complicated. The processes such as cutting, grinding, and drilling have higher requirements, and problems like cracking are likely to occur during the processing.

Both acrylic sheets and glass sheets play important roles in different fields by virtue of their respective unique advantages. Whether you are pursuing aesthetics and safety, or considering processing difficulty and cost, as long as you have an in-depth understanding of their differences, you can make the best use of these two materials, facilitating the implementation of various creative ideas and projects, and bringing more experiences to people's production and daily life.

Guangzhou Goodsense Decorative Building Materials Co., Ltd. provides reliable services for acrylic sheets. We sincerely hope that you will come to consult and discuss cooperation with us!

WeChat YouTube Facebook

Guangzhou Goodsense Decorative Building Material Co.,Ltd

Address: No.107 Guangyuan Road, Tanbu Town, Huadu District, Guangzhou,China

TEL/Phone:+86-13066182261

Skype:het_kelly88

E-MAIL:info@cngoodsense.com